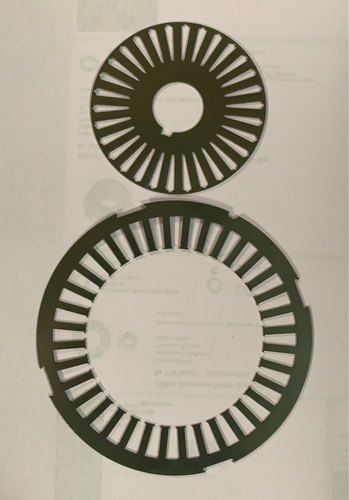

CRNO Motor Stamping

Price 30 INR/ Kilograms

CRNO Motor Stamping Specification

- Product Type

- Motor Stamping

- Material

- CRC

- Surface Treatment

- Polished

- Voltage

- 220-440 V

- Size

- Different Available

- Color

- Silver Grey

- Dimension (L*W*H)

- Custom/As per Design

- Weight

- Variable (depends on size)

- MOQ

- As per requirement

- Usage/Application

- Electrical Motors, Generators

- Insulation

- Available as required

- Finishing

- Smooth

- Feature

- Corrosion Resistant, Precision Engineered

- Application

- AC/DC Motors, Pumps

- Tolerance

- ±0.05 mm

- Packaging Type

- Carton/Box packing

- Technique

- Cold Rolled Non Oriented (CRNO)

- Shape

- Round/Laminated

- Thickness

- 0.35 mm - 0.65 mm

CRNO Motor Stamping Trade Information

- Minimum Order Quantity

- 100 Kilograms

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 10000 Kilograms Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About CRNO Motor Stamping

Owing to rich market experience, we are offering a unique range of CRNO Motor Stamping. It is broadly useful for stamping as well as cores of electrical transformer applications. In addition to this, provided stamping is to reduce the cost of parts as stamps helps to replace part production with its die forging process. CRNO Motor Stamping is avail with a rigid steel construction to require less maintenance. It can be avail at cost effective rates.

Precision Engineering for Maximum Efficiency

Our CRNO Motor Stamping offers top-tier precision, ensuring seamless integration with AC/DC motors, pumps, and generators. With smooth finishing, tight tolerance, and customizable design, these stampings deliver consistent performance, reduce power losses, and enhance the overall efficiency of electrical machinery. Every piece is crafted to meet stringent industry standards.

Custom Solutions for Varied Applications

From standard to bespoke dimensions, our CRNO stampings fit a wide range of electrical motors and industrial applications. Whether you require specific insulation, surface treatment, or size, we accommodate unique requirements. Our flexible MOQ policy and robust packaging ensure quick, hassle-free supply for manufacturers, suppliers, and traders across India.

FAQs of CRNO Motor Stamping:

Q: How is the CRNO Motor Stamping manufactured and what materials are used?

A: CRNO Motor Stampings are manufactured by cold rolling non-oriented steel, using CRC (Cold Rolled Close Annealed) materials. This process delivers precision-engineered, corrosion-resistant, and polished stampings suitable for diverse electrical applications.Q: What thickness options are available for these motor stampings?

A: We offer CRNO motor stampings in thicknesses from 0.35 mm to 0.65 mm, ensuring compatibility with various electrical motors, generators, and pumps based on performance and design needs.Q: When should I consider using CRNO Motor Stamping for my project?

A: You should choose CRNO motor stamping when your project requires high-performance, corrosion-resistant, and precision-engineered components for AC/DC motors, generators, and pumps, especially where efficiency and custom sizing are critical.Q: Where do you supply these CRNO Motor Stampings?

A: We distribute, manufacture, and supply CRNO motor stampings to customers across India, addressing the needs of manufacturers, distributors, traders, and wholesalers in the electrical industry.Q: What is the process for customizing dimensions, insulation, and packaging?

A: Simply share your specific design, insulation, and packaging requirements with us. We provide custom-built solutions with dimensions, insulation options, and durable carton/box packaging tailored to your application and logistics needs.Q: How can these CRNO Motor Stampings be used in industrial applications?

A: These stampings are ideal for use in AC/DC motors, electrical generators, and pumps, providing high conductivity, minimal energy loss, and lasting durability for efficient industrial operation.Q: What are the main benefits of using your CRNO Motor Stampings?

A: Our stampings offer precise dimensions, excellent corrosion resistance, smooth finish, and low tolerance levels, contributing to better motor performance, extended equipment life, and reduced energy losses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Motor Stamping Category

CRCA Motor Stamping

Price 90 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : SHREE ARYA ENGINEERING

Surface Treatment : Polished & Coating

Material : CRC, CRNGO

Size : Customised

IE 2 Motor Stamping

Price 225 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Product Type : Motor Stamping

Surface Treatment : Polished

Material : CRC

Size : Different Available

Decarb Annealed Stamping

Price 85 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Motor Stamping

Surface Treatment : Polished

Material : CRC

Size : Different Available

Cooling Tower Motor Stamping

Price 125 INR / Kilograms

Minimum Order Quantity : 100 Kilograms

Product Type : Motor Stamping

Surface Treatment : Polished

Material : CRC

Size : Different Available

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry